GSK 980TDi Turning Machine CNC Controller

Basic Info.

| Model NO. | GSK 980TDi |

| Numerical Control | CNC/MNC |

| Processing Precision | 1μm |

| Performance Classification | High-End CNC Machine Tools |

| Certification | CE, ISO 9001, ISO 50001:2018;ISO45001:2018;Is014001:2015; |

| Condition | New |

| PLC | Online Editing |

| Connection | Full Bus |

| Interface | RS232&USB&Network |

| Materia | Metal |

| Displayer | 8.4-Inch &10.4-Inch Screen |

| Type | CNC Controller |

| Transport Package | Carton or Plywood |

| Trademark | GSK |

| Origin | Guangzhou, China |

| HS Code | 8537101901 |

| Production Capacity | 100000set/Year |

Product Description

Product Description

GSK980TDi TURNING MACHINE CNC PRODUCT BRIEF

GSK980TDi is a new member of the GSK980TD series product, which is developed by the original engineers who have studied the GSK980TD, GSK980TDa, GSK980TDb and GSK980TDc, etc. products, as well it is the newest product followed with the GSK980TDc, which GSK aims at the common CNC Turning machine and Turning center market. GSK980TDi is based upon the GSK-Link industry spot BUS, which is adapted with the BUS servo drive unit and multi-core 23-bit absolute encoder servo motor, carries out the 0.1μm level position accuracy, servo parameter on-line configuration and non-block mechanical zero return. Simultaneously, invite the known professionals in the industry field to design the newest appearance. Additionally, the project team has been carried out a large number of studies in the efficiency improve, intelligence application, humanization operation and user secondary development, etc. The launch of the GSK980TDi will lead another significant revolution in the common CNC system!

| Technical features |

| Based on GSK-Link industrial field bus. |

| Least command increment: 0.1μm, maximum traverse rate: 100m/min. |

| Support turning and milling. |

| Support torque control . |

| Support servo parameter online configuration, servo status real-time monitoring. |

| Support display interface secondary development (User-defined). |

| Support non-stop mechanical zero return. |

| Standard bus servo drive unit and multi-turn 17-bit absolute encoder. |

Based on GSK-Link industrial fieldbus,servo motors equipped with GR-L series servo devices and 25-bit or higher high-resolution absolute encoders can achieve nano-level interpolation.so that the output accuracy of the system matches the feedback accuracy of the servo motor encoder, giving full play to the performance of high-resolution encoder servo motors,thus achieving high-speed, high-precision processing results.Oscillating chip break

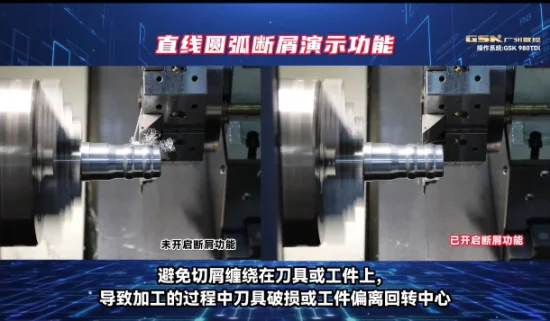

During the roughing process, a certain frequency of sine/cosine wave interference is applied to the feed axis to cause the tool to oscillate in the direction of the cutting track, breaking the continuous chips into pieces and avoiding the chips from winding around the tool or the workpiece, thus causing the tool to break or the workpiece to deviate from the center of rotation during the machining process.Support turning, milling and drilling complex machining

The system has 5 feed axes and 2 analog spindles. When the servo spindle is adapted, spindle orientation, rigid tapping, cylindrical interpolation, and polar coordinate interpolation can be realized to meet the requirements of turning and milling.

Backstage editing

During the program processing, other different programs can be edited,fully using of system resources,rational planning of time,and improving the efficiency of operation of the machine.Graphical simulation

During the program processing, the workpiece entity is used as a model to simulate the real processing scene of the workpiece, and the tool path is more intuitive and easier to check the programming errors.

Manual MST function

Users can start MST commands in the position screen in manual/MPG mode, which reduces page switching and makes the operation more centralized and easy for users to quickly operate the machine

The torque control function controls the motor to rotate at a certain rate, with a certain moment as the termination condition of the rotary motion. When the motor reaches the required torque, the current torque is maintained, so that the motor achieves dynamic balance with the external force in the rotation direction, which can be used for work piece docking and tailstock control between spindles.Thread repair function

The thread repair function allows the machine to repair damaged threads (large oil pipelines or screw) regardless of whether the machine tool is equipped with a servo spindle or an analog spindle.Polygon turning

| For traditional polygon processing, power milling tools are usually used for processing. For occasions where high precision is not required the polygon turning function can be used to accelerate the processing of various polygons by the offset angle before synchronizing the workpiece axis with the main control axis and changing the speed ratio of the workpiece axis and the tool axis. |

The machine tool diagnostic function visually visualizes the input and output signals of the machine tool on the machine structure drawing, making the fault display of the machine tool more intuitive and convenient for troubleshooting machine problems.Application caseGSK980TDi applied in Brake Pad Machining

| Special type: Brake pad processing machine |

| Application effect |

| Driving linear and rotary axes with a general servo drive; |

| The grinding wheel is machined with end faces instead of the side of the common grinding wheel; |

| Complete tasks with dedicated instructions |

Technical specification

Company ProfileGSK CNC Equipment Co., Ltd. (hereinafter referred as GSK) is specially devoted to conducting research and practice of basic equipment industrial development, providing "trinity" packaged solutions of machine tool CNC system, servo drive and servo motor, taking initiative in the expansion of industrial robot and all-electric injection molding machine field, developing the new marketing mode of machine tool exhibition hall, providing the customers with all-round professional machine tool remanufacturing solutions and services, promoting the integration of production and education, setting up the vocational education and training institute, as well as conducting highly skilled CNC personnel training. It has developed into a high-tech enterprise integrating science, education, industry and trade, thus being known as "China Southern CNC Industrial Base". Adhering to the corporate philosophy of "making itself a century-old enterprise and building gold quality" and the service spirit of "keeping improvement and making users satisfied", GSK enhances the user product value & benefits through continuous technological progress and innovation, and makes unremitting efforts to promote the localization process of basic equipment industry, improve the technological level of the industry, and promote the development of China's national equipment manufacturing industry.

Main products:

GSK CNC System Idustrial robot

Full electric injection molding machine CNC machine

our partners

218MC USB Reading Problem Solution

218MC USB Reading Problem Solution